Ultrasound is the sound above the human hearing range having shorter wavelengths. Though ultrasound starts at 20 KHz and above most ultrasonic transducers start from 200 KHz. The ultrasonic transducers are sensors that work by using ultrasonic sound waves. These transducers convert the electrical signals to ultrasonic waves or vibrations which are focused on the intended object. Once the ultrasonic waves reach back to the transducer, the distance between the objects can be measured by the intensity of sound. Transducers are used in a variety of fields. The shorter wavelengths generated by ultrasonic transducers are used for measuring materials and distances and for non-destructive testing. The ultrasonic probes or transducers are the necessary part of any ultrasonic test. Transducers can be used for sensitivity or resolution. Sensitivity is the transducer’s ability for detecting small defects in materials while the resolution is the ability to separate signals.

How Ultrasonic Transducers Work

When electricity is supplied to the transducer, it vibrates at a certain frequency and an ultrasonic sound wave is produced having a frequency of 40 kHz. The sound waves are focused and travel in a certain direction, if there is any obstacle in the path an echo will be produced, and the sound waves will bounce back and reach the transducer which will convert the echo into an electrical signal. The transducer can calculate the distance between the object and the transducer by the time interval between when the original sound wave was released and when the echo from the obstacle was received. These ultrasonic probes or transducers have an advantage over infrared sensors as they are not affected by black particles or smoke in the surroundings and are better at suppressing interference from the background than infrared ones. These transducers are generally used for calculating the distance by the use of ultrasonic waves.

The Formula for Measuring the Distance

D = ½ * T * C

Where D= Distance

T=Difference in time between sending and receiving ultrasonic waves

C= Sonic speed

Ultrasonic transducers types

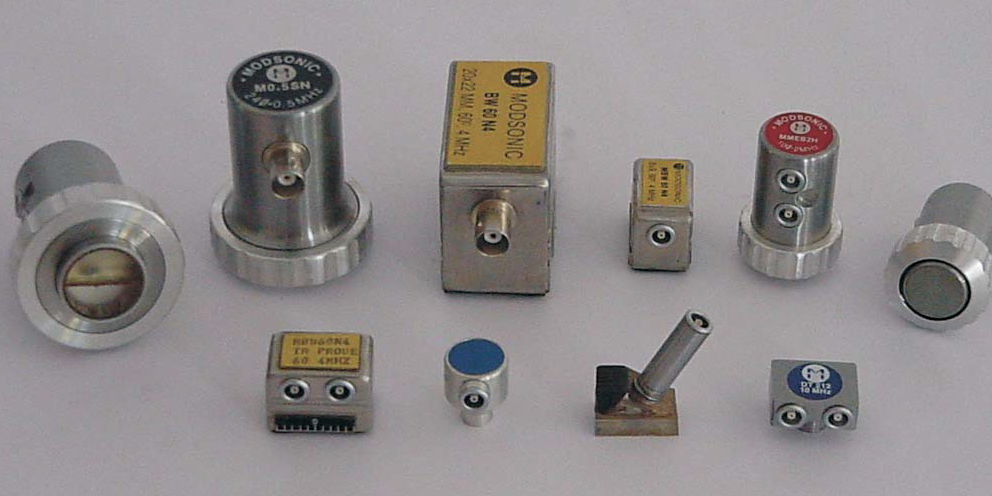

These transducers are of many different types depending on the factors like piezoelectric crystal arrangement, frequency, and footprint. Ultrasonic transducer price is dependent on the type of transducer. Some of them are given below.

a. Linear Transducers – These transducers have a linear piezoelectric crystal arrangement. Piezoelectric crystals include some types of ceramics, Rochelle salt, and quartz crystals. These transducers are versatile and generally used everywhere.

b. Standard Transducers – Also called convex transducers, these have curved piezoelectric crystals. These are best for in-depth examinations.

c. Phased Array Transducers – These are low-frequency transducers of center frequency between 2 MHz to 7MHZ with small footprints.

d. Straight Beam Contact Transducers-These are used to introduce longitudinal waves into a material. Straight Beam Contact Transducers are used for direct contact with the material being tested.

e. Angle Beam Transducers-These types of transducers are used to produce longitudinal waves in the material to be tested.

f. Dual Element Transducers- These transducers use different elements for transmitting and receiving ultrasound signals. These are used to detect irregular defects mainly caused by pitting and corrosion.

g. Immersion Transducers- These types of transducers are better than contact-type transducers. There is a reduction in variations in sensitivity due to their uniform coupling. These are also faster due to their automated scanning ability. Also, these are better posed to detect small defects.

h. Some other transducers are Contact transducers, Air coupled ultrasonic transducers, and Delay line transducers among others.

Different Applications

Transducers are used in various fields including industrial and medical fields. Ultrasonic waves generated by them help find the specified targets, measure the distance between the targets and the transducers, finds the levels or depths, and finds the exact location of an intended target.

a. Application in Medical Field

Ultrasonic probes are used for diagnostic tests, testing of internal organs like heart, eyes, and uterus, and even in oncology. Doppler motion study is only possible due to the use of these types of transducers. Ultrasound generated by transducers helps in reducing joint pains and cauterizing tumors which require localized heating. Ultrasonic transducers are also helpful in removing bladder and kidney stones due to the vibrations it produces.

b. Application in Industrial Field

Transducers are used in production line management, detecting broken down wires, for counting of workers, assessment of liquid levels, detecting vehicles, and measuring the distance between certain objects among others.

c. Ultrasonic transducer for cleaning purposes

These transducers are used for cleaning purposes too. These transducers emit ultrasonic vibrations in liquid tanks where objects are placed for cleaning, these vibrations and liquid cavitation due to ultrasound result in turbulence in liquid, and thus cleaning is achieved. Ultrasonic cleaning is mainly done for cleaning jewelry, small machinery, surgical instruments, dentures and for degreasing too. Ultrasonic cleaners are also being employed in assembly lines for large-scale cleaning.

d. Chemical uses

The cavitation that happens due to ultrasound by transducers results in an electric discharge. Thus, ultrasound acts as a catalyst in chemical reactions like polymerization and depolymerization, oxidation and reduction, molecular rearrangement, and hydrolysis. Due to ultrasound acting as a catalyst, many chemical processes are efficiently done at low temperatures at a far greater speed than was possible before.

Advantages of Ultrasonic Transducers

Some advantages of transducers are given below.

a. These transducers can sense and are able to measure in a wide variety of materials.

b. These transducers are impervious to dust, water, and temperature variations.

c. Well suited for work in any type of environment.

d. These transducers can measure high distances too.

Conclusion

So, this was a brief description of ultrasonic transducers types. These devices are used for wide-ranging purposes main among them being measuring the distance between different objects in a variety of micro and macro environments which helps in completing the task efficiently.

Modsonic Instruments has in its range a variety of Transducers as standard and custom in different configurations of Frequency, Element Diameter, Connector Styles etc.

With the expertise and experience of 30 years we also have developed “Pro Series” Transducers with composite crystals for better sensitivity, resolution and penetration Please visit us at modsonic.com for more information on our products.