What is a Digital Ultrasonic Flaw Detector? How Does it Work?

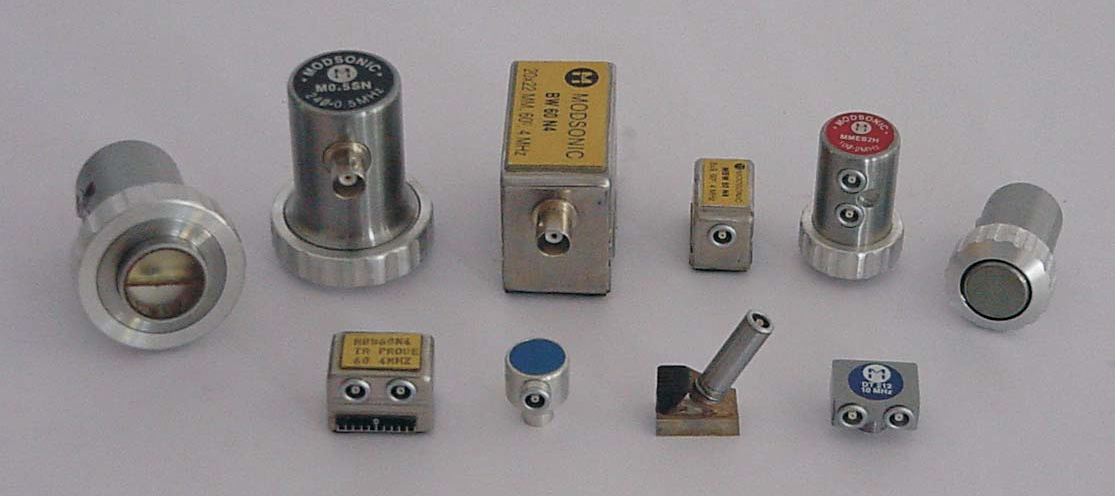

Digital ultrasonic flaw detectors are modern age portable and processor-based flaw detectors. They are made up of parts including an ultrasonic transducer, hardware & software for capturing signals and analysing them, a data logging module, and a waveform display for viewing the images and graphs. The returning ultrasonic signals are processed digitally through these instruments for…

Details