Ultrasounds are the sound waves that vibrate above the human hearing range. These have shorter wavelengths that start from 20 kHz onwards. Most of the ultrasonic transducers use ultrasound wavelength frequencies that start from 20 kHz.

What is Frequency?

Frequency is the number of waves or signals that can appear in a fixed period. Hertz (Hz) is the unit of frequency. Frequencies have different ranges. These vary from low to high. They are as follows.

a. Very Low Frequencies (VLF)- 3 to 30 kHz

b. Low Frequencies (LF)- 30 kHz to 300 kHz

c. Medium Frequencies (MF)- 300 to 3000 kHz

d. High Frequencies (HF)- 3 MHz to 30 MHz

e. Very High Frequencies (VHF)-30 MHz to 300 MHz

f. Ultra-High Frequencies (UHF)- 300 MHz to 3000 MHz

g. Super High Frequencies (SHF)- 3 GHz to 30 GHz

h. Extremely High Frequencies (EHF)- 30 GHz to 300 GHz

What is an Ultrasonic Transducer?

Ultrasonic transducers are sensors that use ultrasonic sound waves for their working. Ultrasonic transducers generate ultrasonic waves through electricity that are targeted in a medium to the intended object. Through the timing and intensity of the returning ultrasonic waves, various measurements can be done. These include distance, the thickness of materials, and other measurements that are essential for the working and safety of the projects and sites. Transducers generally operate over the 20 kHz frequency range and are available as active and passive transducers.

How do Ultrasonic Transducers Work?

Ultrasonic transducers are made from piezoelectric materials such as ceramic or quartz. These materials physically change shape when excited by an electrical pulse. These electrical pulses are switched on and off in rapid succession, which causes the piezoelectric materials to vibrate at high frequencies. The transducers are attached to a diaphragm that causes the ultrasonic sound waves to generate.

These are low-frequency ultrasonic waves having a frequency up to 40 kHz. These sound waves are directed towards a certain object or material in a medium for different purposes. It may be for measuring the distance, or thickness of a material or any other flaws. When the ultrasonic waves encounter any obstacle, they bounce back to the transducer. These are again converted to electric signals that are interpreted to get accurate results.

For measuring the distance, the following formula is used.

D = ½ * T * C

Where D stands for Distance

T stands for the difference in time between sending and receiving ultrasonic waves

C stands for Sonic speed

Types of Ultrasonic Transducers

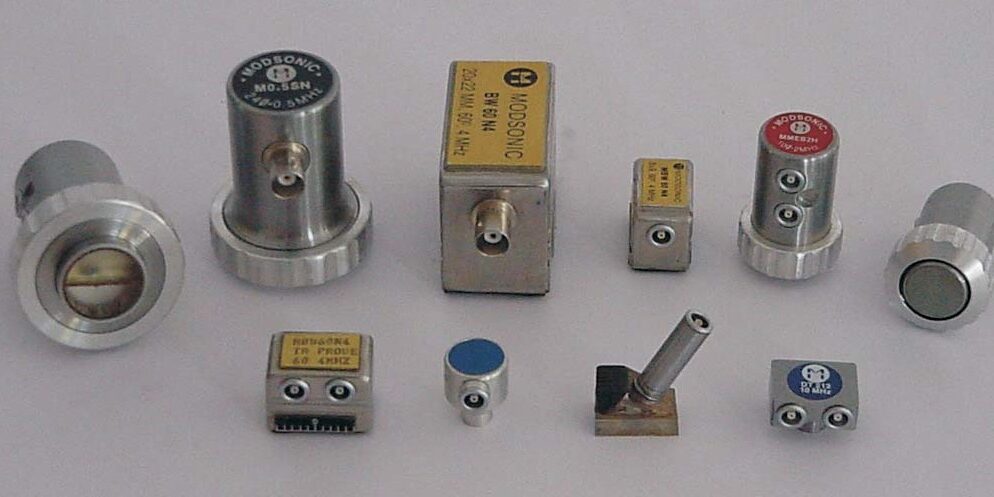

Ultrasonic transducers differ on the type of functions, frequency generated piezoelectric crystal arrangement, footprint among other factors. Some of the transducers generally used are as below.

1. Standard Transducers

Standard ultrasonic transducers use a curved piezoelectric crystal arrangement. These are also known as convex transducers and are used for in-depth examinations.

2. Linear Transducers

Linear ultrasonic transducers are versatile and used for a variety of purposes. These use a linear piezoelectric crystal arrangement.

3. Phased Array Transducers

Phased array transducers are instruments of low-frequency variety that range from 2 MHz to 7 MHZ and have small footprints.

4. Dual Element Transducers

Dual element transducers as the name suggests have separate elements for transmitting and receiving ultrasound signals. These transducers can detect irregular defects that are due to pitting and corrosion.

5. Straight Beam Contact Transducers

Straight beam contact transducers can be directly applied to the material being tested. These work by targeting longitudinal waves into the material being tested.

6. Immersion Transducers

Immersion transducers are considered better than contact-type transducers as they are faster due to their automated scanning capability. Due to their uniform coupling, they can detect minute defects with fewer variations in sensitivity.

Other than the devices mentioned above, there are other types of ultrasonic transducers like Angel Beam Contact transducers, Delay line transducers and Air coupled ultrasonic transducers, and many more.

How do Ultrasonic Transducers Work-Different Use?

Ultrasonic transducers are applied in different commercial fields. These are used for measuring distances, specified targets and their exact locations, and for determining different depths and levels.

a. In Industrial Field

Ultrasonic Transducers are used in different fields of manufacturing, production, oil exploration, and drilling. These include production line management, counting workers, detecting objects and vehicles, detecting broken down wires, liquid level assessment, and of course for measuring the distance. Ultrasonic transducers in the form of cleaners are also used for cleaning small machine parts, jewelry, dentures, surgical instruments, and also for degreasing.

b. In Medical Field

Ultrasonic probes are a form of ultrasonic transducers that are used for diagnostic tests. These are also used to test vital organs like the eyes, heart, and uterus as ultrasonic testing is a non-invasive method. These are also used in physiotherapy to reduce joint pains through vibrations. Due to this feature, a form of transducers is also used for removing bladder and kidney stones.

c. In Chemical Industry

Ultrasonic transducers through the generation of ultrasonic waves cause cavitation that further generates an electric discharge. The discharge works as a catalyst in several chemical reactions. These reactions include oxidation and reduction, polymerization and depolymerization, molecular rearrangement, and hydrolysis. These chemical reactions now occur at far low temperatures and at greater speeds. This saves time, increases production, and also leads to considerable savings in energy costs.

Benefits of Ultrasonic Transducers

Ultrasonic transducers have several benefits and advantages. Some of these are mentioned below.

1. Ultrasonic transducers are even better than infrared sensors. These are not hampered by dust, black particles, water, smoke, and even temperature variations. Thus, ultrasonic transducers suppress background interference better than other infrared devices.

2. Ultrasonic transducers are used for accurate measuring of different elements like minute defects, low depths, and high distances.

3. Ultrasonic transducers can work in several types of mediums, materials, and environments. These are easy to carry and can be taken to difficult-to-reach sites without any hassles or difficulties.

Conclusion

So, this was a brief description of the working of ultrasonic transducers, and their types and benefits. These versatile instruments are used for a variety of purposes especially measurement of distances, thickness, and depth levels in a wide range of micro and macro environments.